Analysis of safety-critical dynamically stressed assemblies

Category A bolted connections in accordance with VDI 2862 are connections whose failure could lead to physical danger or even pose a threat to life.

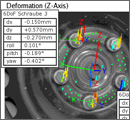

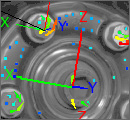

With the help of a 3-D camera system, ABC analyzes these safety-critical connections (which are dynamically stressed) for deformations in the entire connection. This contact-free process pursues the following goals:

- Analysis of the causes of a fastener's failure or the potential failure of a connection (e.g. loss of preload, self-loosening, fatigue fracture)

- Effective support of FEM calculations through real input parameters (3-D deformations)

- Targeted structural improvement of the entire connection

- Possible omission of complex safeguards (serrations, adhesive locking devices, etc.)

- Weight and cost optimization

Examples: Accompanying measurements at test stands, in tests facilities, etc.

- Wheel bolt systems (measurement of the deformations of hub, brake disk, wheel, wheel bolt)

- Highly stressed chassis fasteners

- Brake caliper fasteners

- Engine fasteners

Measuring the preload with ultrasound and other measuring procedures

Knowledge of the preloads during assembly and operation is of decisive importance for the functional reliability of a bolted joint. With the help of special measuring techniques, preloads can be precisely measured, allowing connections to be safely designed.

Practical application testing

With the help of measuring instruments tailored for mobile use, fastening systems can be tested at test stands and in the vehicle itself and safeguarded for the start of production.